The desire for energy security and (lack of) climate change are driving two

avenues of innovation to power the next generation of vehicles. The first avenue

is to invent new fuels, such as bio-fuels, that change the supply dynamics of

the industry. The second avenue is to invent entirely new engine concepts to

improve efficiency. One such concept, using

detonations (as opposed to

deflagrations) to combust fuel and

air mixtures, has been investigated since the

1940’s.

Using detonations allows for much higher efficiency engine operation. One of the

most common types of detonation engines is the Pulsed Detonation Engine (PDE).

Unfortunately, due to many difficulties including the intermittent nature of

thrust from such engines, no PDEs have been commercially produced to date

(although the concept has flown in an Air Force test plane).

In a recent review paper, Kailasanath has discussed the history and current work

on a similar detonation engine concept, called a Rotating Detonation Engine

(RDE). An RDE is a similar concept to a PDE in that it uses detonation to burn

the fuel and air, but the RDE offers some advantages over the PDE, primarily

that the detonation is continuous in an RDE. This means that an RDE can generate

thrust continuously instead of intermittently. In addition, the continuous

operation of an RDE allows it to have higher efficiency than a PDE.

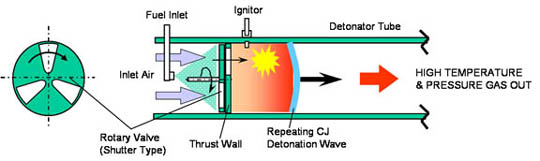

A typical PDE is not much more complex than a cylinder containing a combustion

chamber, into which fuel and air are fed, an ignitor and a nozzle to generate

thrust. The fuel and air are pulsed into the combustion chamber, ignited into a

detonation, and expanded through the nozzle, with the detonation traveling along

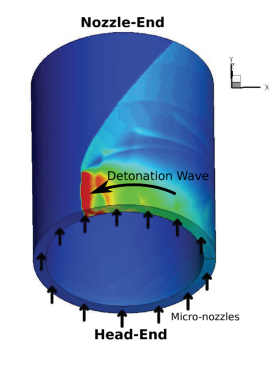

the long axis of the cylinder. An RDE, by contrast, is more complex. A typical

RDE configuration is a ring-shaped cylinder, where fuel is fed from one end of

the cylinder and a nozzle is at the other end of the cylinder. The detonation

wave travels tangentially around the cylinder, burning the fuel and air as they

are fed into the ring. At the other end of the chamber, the gases are expanded

through the nozzle to generate thrust. This is different from a PDE, where the

detonation wave travels from the front of the cylinder to the back along the

long axis, while in the RDE the detonation wave travels circumferentially around

the cylinder. The following pair of images shows the difference between the

operation of each type of engine. It is important to note that the Rotating or

Pulsed indicates the nature of the combustion wave - not the rotation of parts

in the engine.

Example Schematic of a Pulse Detonation Engine. Source: UCLA Energy and Propulsion Research Laboratory

Example schematic of a Rotating Detonation Engine. Source: Kailasanath

According to Kailasanath, research into RDE’s began in the late 1950’s and early

1960’s, and focused primarily on application of RDE’s to rocket propulsion. More

recent research has extended the usefulness of RDE’s to air-breathing propulsion

(i.e. jet-engine-like propulsion). In addition to this experimental work, other

recent work has focused on modeling RDE’s using computer code. These computer

simulations have been used to investigate the overall flow field in an RDE as

well as the performance of an RDE as various engine operating parameters are varied.

Two of the primary control parameters available to experimenters (and the

parameters that are varied in the simulations mentioned above) are the pressure

of the fuel and the air at the inlet, and the pressure at the nozzle end of the

engine, called the inlet pressure and back pressure respectively. Because of the

conditions in the combustion chamber of a detonation engine, the mass flow rate

of the fuel and air mixture through the engine depends only on the inlet

pressure (and not on the back pressure), but the thrust of the engine depends on

both parameters. Interestingly, the specific impulse (a measure of the

efficiency of the engine) depends only on the ratio of the inlet and back

pressures, but not on specific values of either parameter. The maximum value of

specific impulse achieved in this study was about 33% higher than a comparable

PDE, confirming the advantages that RDE’s should have over PDE’s. The author

concludes by noting that the value of specific impulse computed in their study

is quite close to the theoretical ideal efficiency, and further optimizations of

the engine may allow the RDE to get even closer to the theoretical maximum.

Citation: K. Kailasanath, “The Rotating-Detonation-Wave Engine Concept : A Brief

Status report,” 49th AIAA Aerospace Sciences Meeting, 2011, Paper

AIAA-2011-0580.